I’ve been rather enjoying myself while adding the accessories to the motor—taking it slow, working generally when the weather is nice and making steady progress.

Last week I tackled the PCV system, throttle linkage, soup can reservoir and the carb (temporarily, as I need new gaskets). I also installed the water pump and the heater hoses.

Today, I was determined to finish the cooling system. I cleaned up the radiator, then put it in after the fan and overflow tank were in place.

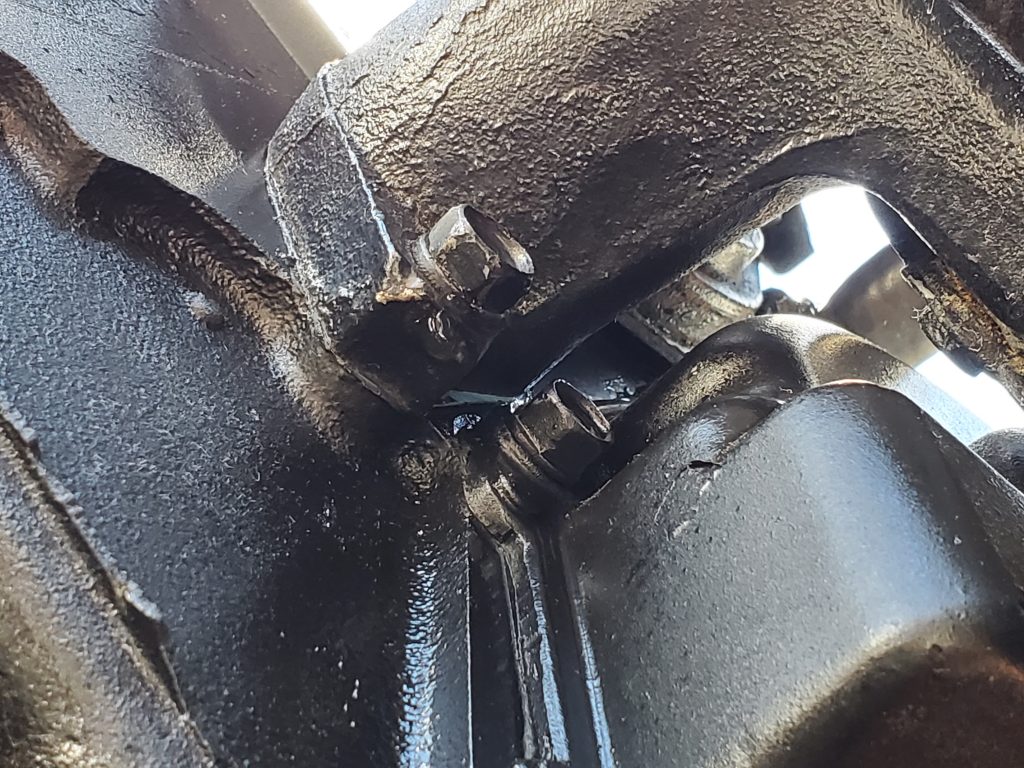

Everything was going well until I added coolant. Even with no pressure in the system, there were two small leaks: one from the water pump, apparently seeping out around one of the bolts.

This is probably my fault. I had to loosen the pump after it was on for an hour when I realized I forgot that tiny hose that connects it to the manifold. The sealant was still wet after removal, so I figured I could get away with reusing the gaskets.

Apparently not!

The second is some weeping around a freeze plug, which I really can’t explain. These I installed some time ago, even taking the precaution of adding a little sealant around the opening before I drove it in. I can’t see any reason for it to leak, nor what I can do different when I replace it.

Before quitting for the day, I drained the new coolant. I’ll probably take a couple of days off before digging back down to the pump. With the coolant out, I’ll likely tackle the plug then, too, though I’m not looking forward to that at all.