I actually took the car out for a spin yesterday—not far, and not fast, but still a good feeling to feel it moving again.

It took the better part of the afternoon to get the last bits and pieces in place. Earlier in the week, I installed a new solenoid, fixed some broken wires at the alternator and lubed the new suspension pieces. Yesterday, with my son helping, we located TDC and installed the distributor with a few degrees(more or less) of advance. Those were the bigger hurdles.

Looking around, there was still plenty to do: throttle linkage, vacuum hoses, coolant, etc. For most of these, the hardest part was actually finding the bits and pieces in the shop. It was about 3:00 when we stood up and realized there was nothing else left to do but crank it over.

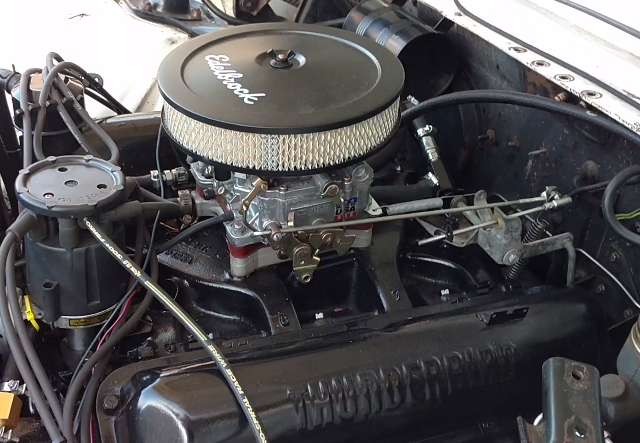

A few shots of starting fluid in the carb, turn the key and—it caught on the first revolution. It took a few starts to get fuel flowing, but within a minute or two, the motor was purring at idle. Oil and fuel pressure were both good, so I set the timing around 18° and let it warm up.

Once up to temp, I revved it up to moderate rpm’s, where it stumbled, shook and backfired—similar, but not identical to the symptoms I had before starting this project.

A little dismayed, we shut it down and installed the power steering pump and the new hydraulic lines I bought months ago. The car was still on jacks in front, so it was a simple matter to start the motor up and bleed the system. (It took about two quarts of fluid before the wipers and power assist were working normally.)

Motor back off, jacked the front end down, kicked the chocks away from the rear wheels and down the driveway we went. The brakes were a little grabby at first—not a surprise—but otherwise the ride was smooth (and it even tracked straight). I took it a couple of blocks up and down the street at parade speed before tucking it into the garage.

It’s pretty remarkable how much went right. From the camshaft to the radiator to the steering box and suspension—a lot of parts were replaced or refurbished. Except for the high-speed stumble (which is a big except), I’m pretty pleased.

I now know that, mechanically, the motor is sound, so the stumble has to be an issue of fuel, or (more likely) ignition. In any case, the goal is to have it sorted out by the time spring rolls around.