Over the last week, I dragged the heads out from underneath the workbench. (Sheesh . . . they didn’t get any lighter over the last six months!) and set about prepping them for install.

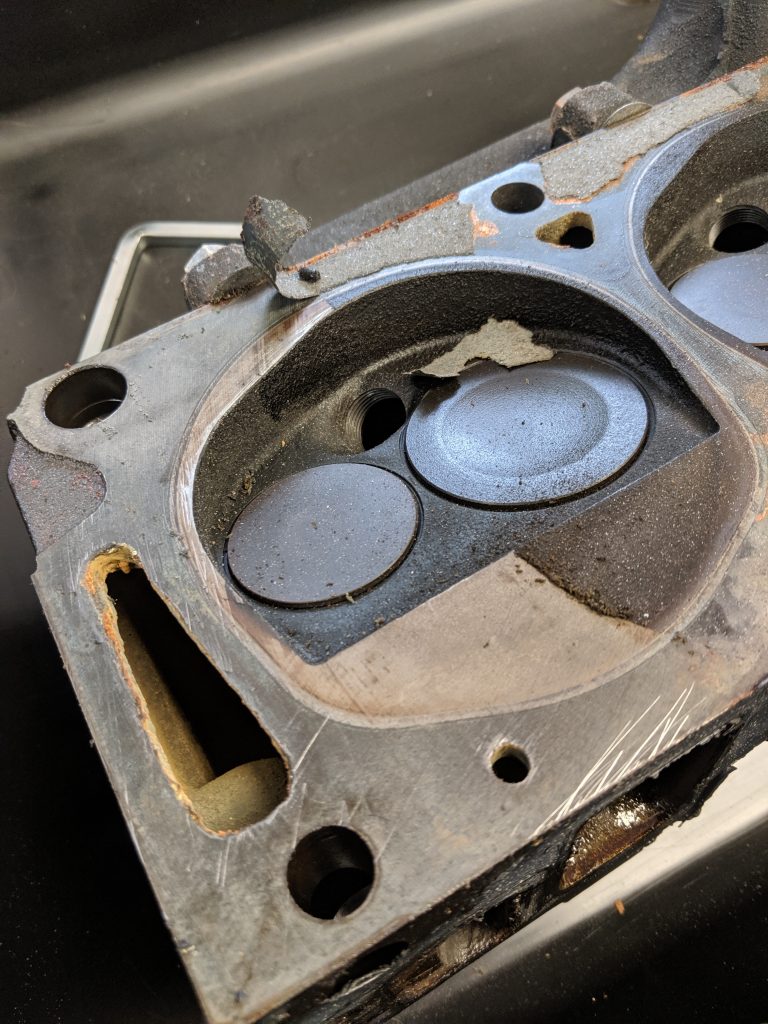

The old gaskets came off easily enough with a new, sharp blade in the scraper. I was surprised at the amount of carbon build up in the combustion areas. These heads were professionally rebuilt and have less than a thousand miles on them since then.

On the first head, I used steel wool and acetone to clean up the recessed areas around the valves. I wasn’t wild about cleaning up the metal fragments, and a little nervous that I might miss some. For the second effort, I used a 3M grey pad with acetone, which worked just as well but without all the worry.

Installation was routine. I ran the head bolts through a wire wheel to ensure the threads were clean. The block, of course, was professionally prepped, so no need to worry about the threads there.

With the block starting to look like an engine again, I started looking around for new valve covers. (Mine were destroyed in the disassembly.) Good originals are getting a little hard to come by, especially the early ones with no PCV vents. Cheap, highly suspect knock-offs are readily available online for less than $50. Pristine restored covers can be had from Bird Nest for $200, but that seemed a tad excessive to me.

I did find a good pair from a junkyard used parts supplier for only $50 each. Or so I thought! They turned out to be truck parts with the “Powered by FORD” imprint instead of Thunderbird, which is, of course, far classier.

A decent pair turned up just in time on eBay, and they were little more than the truck units. They arrived a few days ago, and I hope to begin working on them this weekend.