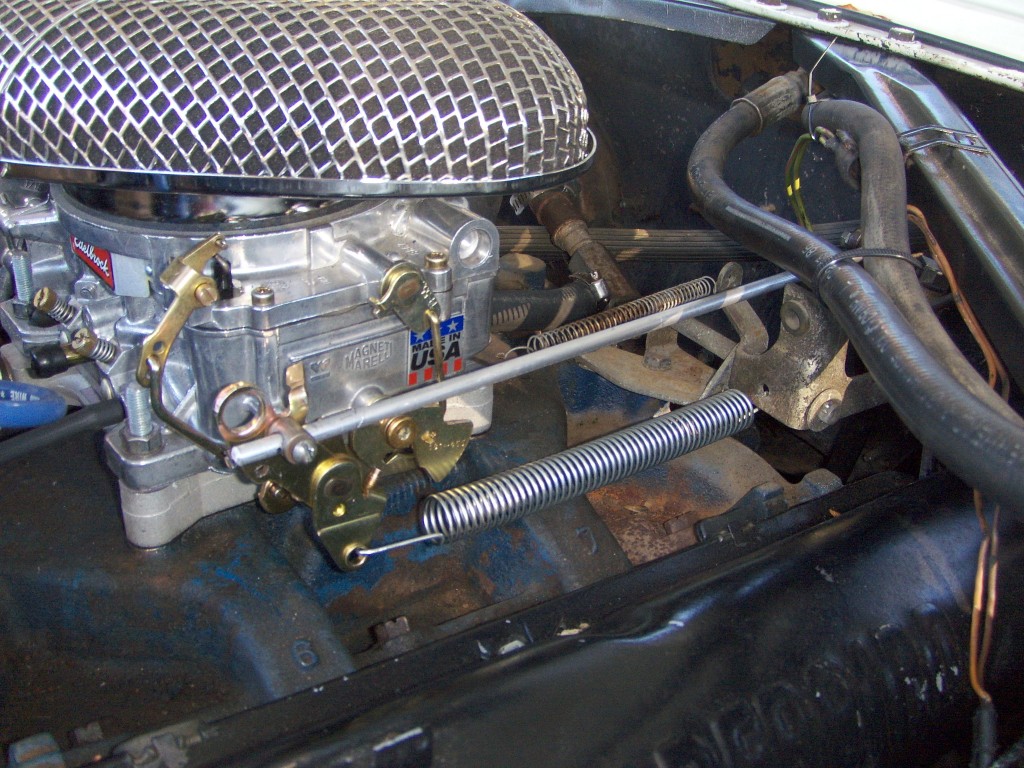

Last week I performed some thorough diagnostics on the motor: checked the vacuum, tweaked the tune on the carburetor, looked at the timing, etc. In the end, the high rpm hot misfire persisted—maybe even got a little worse, as I managed to coax a backfire during one test run.

While I’m not 100% convinced it’s an internal engine issue, I strongly suspect it. (It’s unlikely, but it could still be an ignition issue in the distributor or plug wires.) Digging deeper, I pulled the valve covers and the rocker arm assemblies. There were no bent pushrods and nothing looked terribly amiss at this level, except perhaps an odd wear pattern on the rocker for the #8 exhaust valve. That cylinder was also the low outlier when I did a compression test some years back.

The diagnostic flowchart goes down the rabbit hole at this point, but one strong possibility is an out-of-spec camshaft. So, with help from my son, the engine came out of the car yesterday.

I’ve pulled engines from at least 5-6 cars over the years, and each one of them has been a challenge in some way. The tight fit in the Thunderbird engine compartment had me relying on every bit of that experience. (And I gained even more in this evolution.)

Getting the hood and accessories off was routine, and with the radiator out, the front of the engine is remarkably easy to access. Likewise when the hood came off things like the throttle arm and bellhousing bolts—notoriously difficult to reach—were right there for the taking.

Underneath, the exhaust flange bolts are buried in deep, greasy recesses, and even though these had been removed a few years back when the transmission came out, they were completely frozen. I ended up removing the 16 exhaust manifold bolts instead. (Many were, surprisingly, only finger tight! I guess the exhaust guy I used doesn’t believe in lockwashers).

While lifting the motor, we got hung up on the transmission cooler lines (hate those things, but no damage done) and the motor mounts snagged on the now free-floating (but unremovable) exhaust manifolds. After some head-scratching, we worked it free and the lift had just enough height to clear the radiator support. (The car being up on ramps to facilitate work underneath.)

There’s a paradox to the engine removal in the T-Bird. The motor has to come up a few inches to clear the motor mount studs, but it has to come forward an inch or so at the same time in order to clear the studs on the torque converter. It’s difficult to do both at once. In my case, the converter came partway with the motor and some 4 quarts of transmission fluid poured out the bellhousing until I pushed it back in. I’m not sure if that’s normal on a COM transmission or if I mucked up the front transmission seal.

In any event, with the lifting out of the way, the real work is just beginning.