I’ve spent some time this week pulling the 390 apart, a task that was not as easy as I expected.

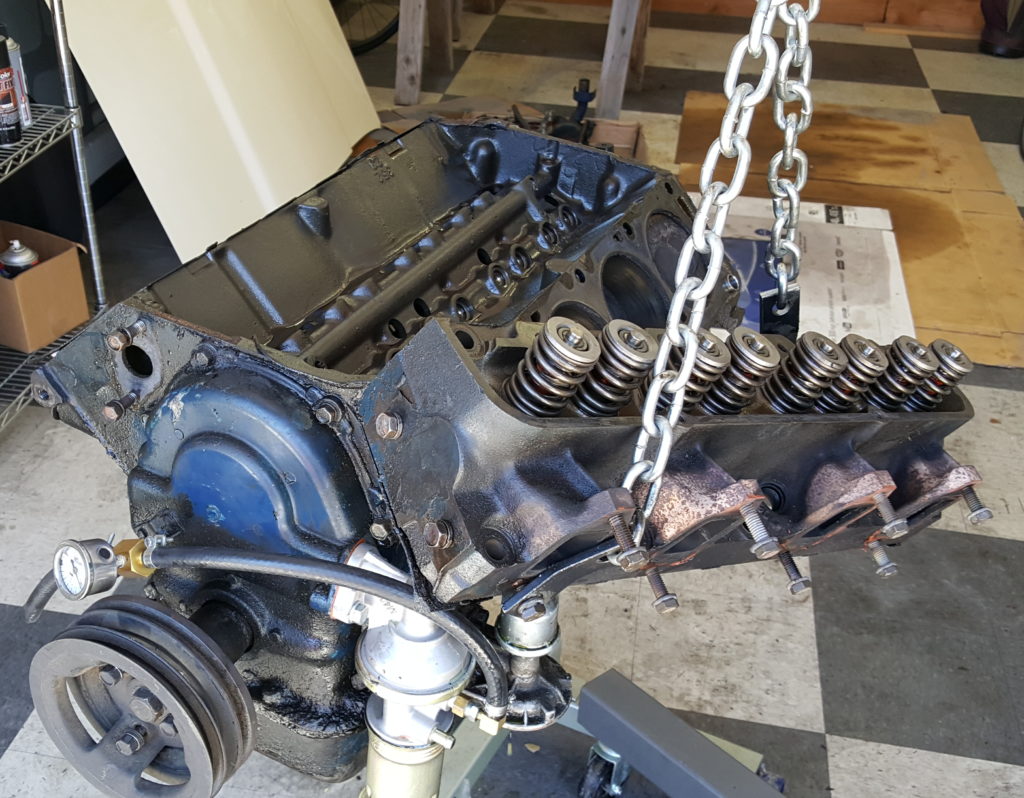

I think the intake manifold is actually heavier than the heads. I had to use my hoist to break it free and lower it to the ground. The head bolts came free easily using a breaker bar. I also used the hoist to separate them from the block and lower them to the floor. (I know from my younger days that it’s a terrible feeling to drop one of these.)

I discovered that the water jacket openings at the back of heads, by the #8 and #5 cylinders, were full of debris and completely blocked. Also, the intake valve in the #8 cylinder is discolored like an exhaust valve—yet another reason to suspect that it’s the source of the misfire.

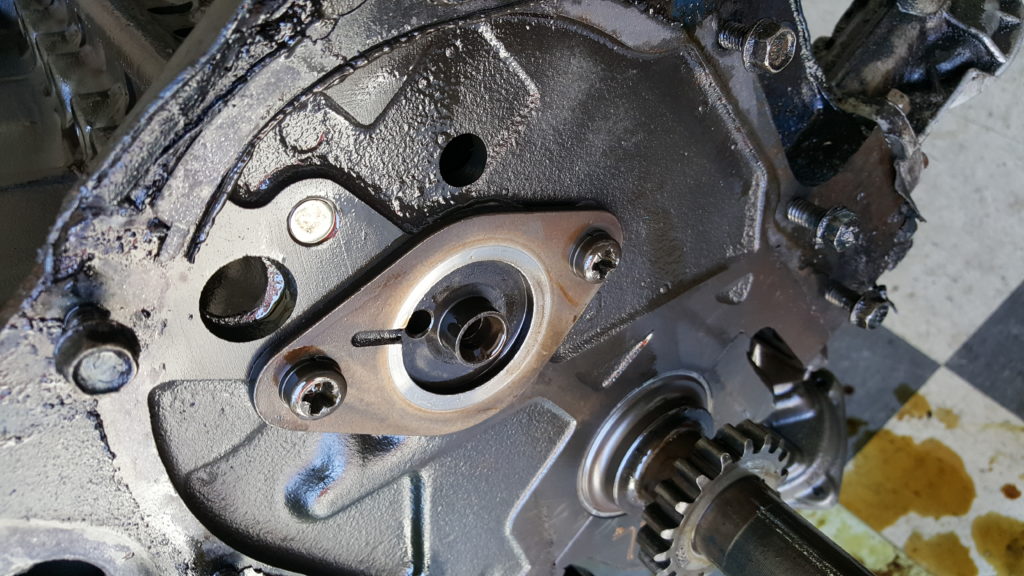

It took a few days to get the harmonic balancer off. I couldn’t budge the bolt with just a breaker bar. I finally found time to pick up a piece of pipe I could slip over the bar to get more leverage. This is normally a terrible idea, since breaking the bolt or the tool is a strong possibility. In this case, I got lucky and the bolt groaned free.

After that, it was pretty simple to get down to the thrust plate, which is held on with big phillips-head screws. I had to give these a tap with a hammer before I could turn them.

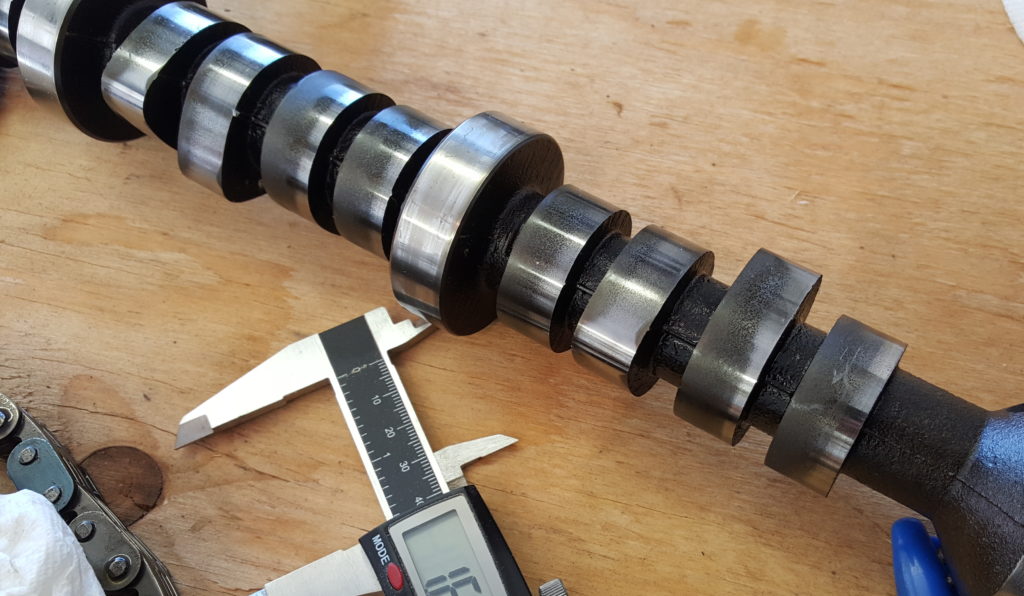

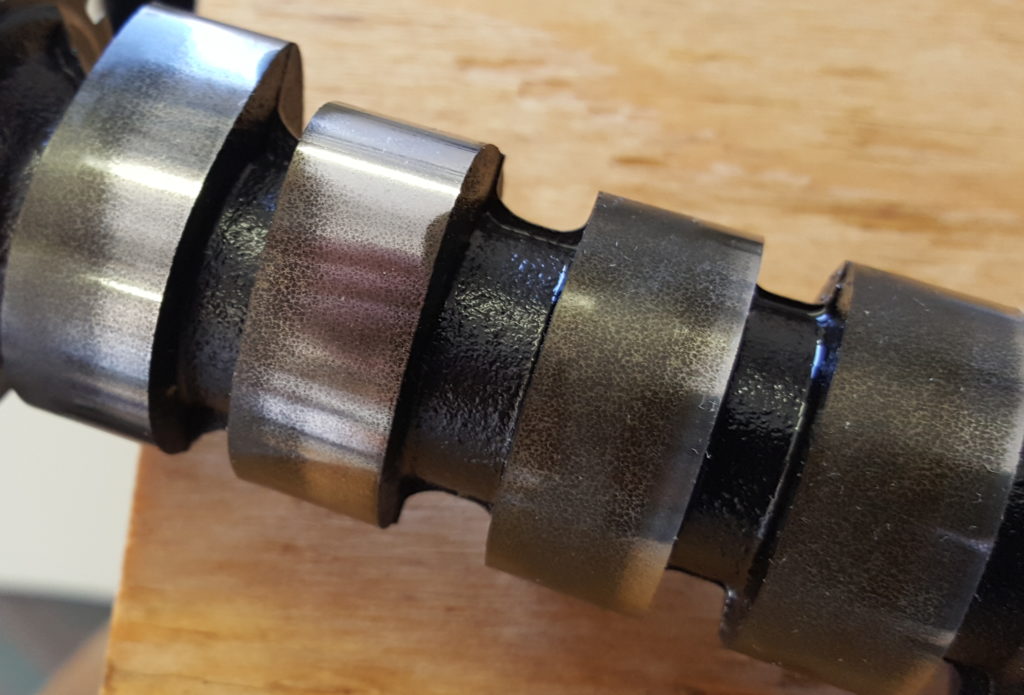

Thrust plate off, I was able to remove the camshaft. I expected it to have some problems, especially down on the end where #8 lives, but it was pretty horrible along the whole length. There was corrosion, pitting, flat spots and uneven wear on every lobe.

I don’t exactly know how the condition of the cam relates to the misfire I was experiencing, but I do know that it needs to be replaced. It also looks like a lot of debris (rust?) has worn off the cam and has been circulating in the oil, so I’ll tear down the rest of the block so it can be thoroughly cleaned and inspected.